Overview

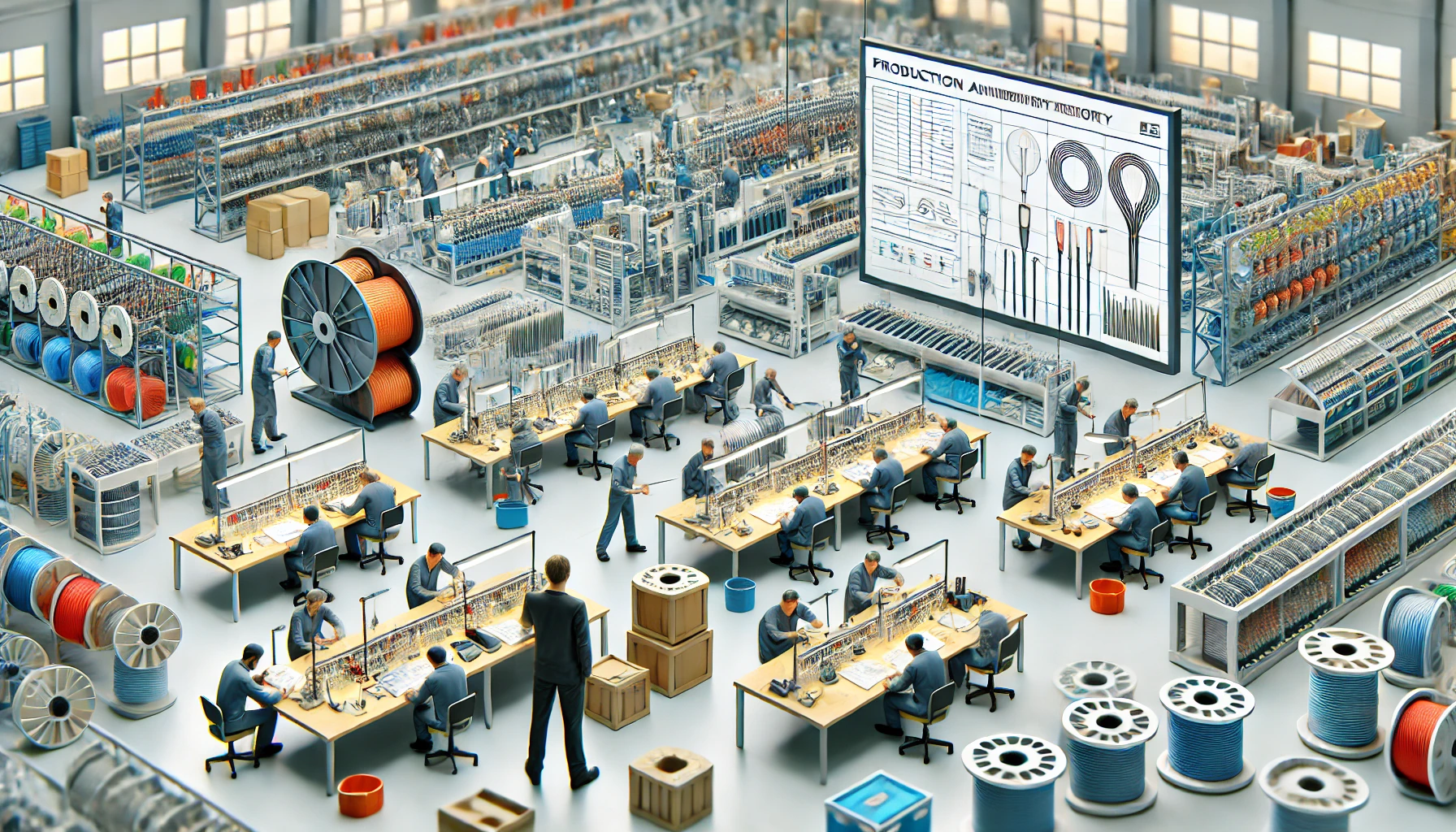

The Resource Planning Optimization System is an advanced solution designed to transform the way a factory with 8,000 workers and over 100 production lines manages its resources. By leveraging sophisticated algorithms and real-time data analysis, the system seamlessly integrates information from incoming orders and key parameters such as production capacity, workforce availability, estimated completion time, and inventory levels to generate comprehensive resource plans across daily, weekly, monthly, and annual cycles.

Each resource plan is meticulously crafted based on various optimization criteria, including minimizing line changeover time, balancing production output across shifts, and optimizing material usage to reduce costs. The system offers multiple planning scenarios, enabling factory managers to choose the most strategic option that aligns with specific business goals—whether it’s maximizing overall productivity, minimizing machine downtime, or improving workforce efficiency.

Through intuitive visual reports and dynamic dashboards, the system empowers management to effortlessly track progress, forecast future trends, and make informed decisions in response to order variations or unforeseen disruptions. This powerful solution not only reduces planning time from several days to just a few hours but also significantly enhances accuracy and efficiency in resource allocation. As a result, production output can increase by up to 20%, while operating costs are reduced by 15%. By deploying this system, the factory gains the agility to quickly adapt to market changes and maintains a competitive advantage in the manufacturing sector.

Functional Modules:

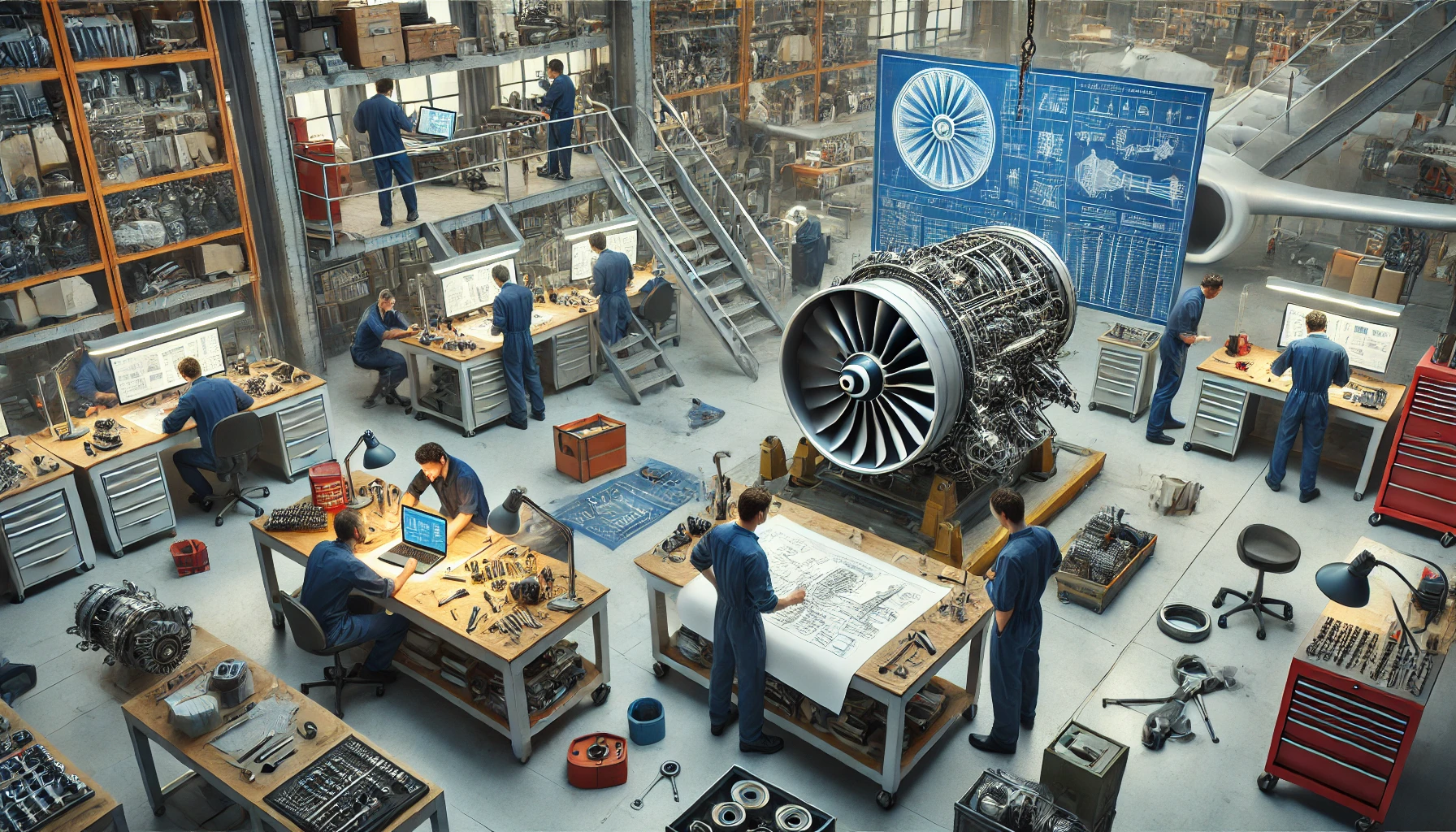

Production Planning Management Module:

- Factory Management

- Production Line Group Management; Production Line Management

- Product Management

- Monthly Working Day Management; Shift Management; Leave Management

- Production Planning Management: Production Plan List; General Production Plan Setup; 3-Month Production Plan Overview; 3-Month Draft Plan Setup based on Predefined Rules; 3-Month Production Plan Setup; Monthly Production Plan Overview; Monthly Production Plan Setup; Daily Production Plan Overview; Daily Production Plan Setup; 3-Month Production Plan Balancing; Monthly Production Plan Balancing; Daily Production Plan Balancing; Import; Export; Plan Duplication.

- PO Management: PO List; Add New PO; View PO Details; Update PO Information; Delete PO; Import; Export.

- Work Team Management: Work Team List; Add New Work Team; View Work Team Details; Update Work Team Information; Delete Work Team; Import; Export.

Reporting Module:

- Reports: Overview Dashboard; Alert Report; Production Output Report; Human Resources Report; KMH Report; Shift Report; NAIJIW Report; Production Adjustment Report; Quick Search Filter.

System Administration Module:

- User Management

- Role Management