Overview

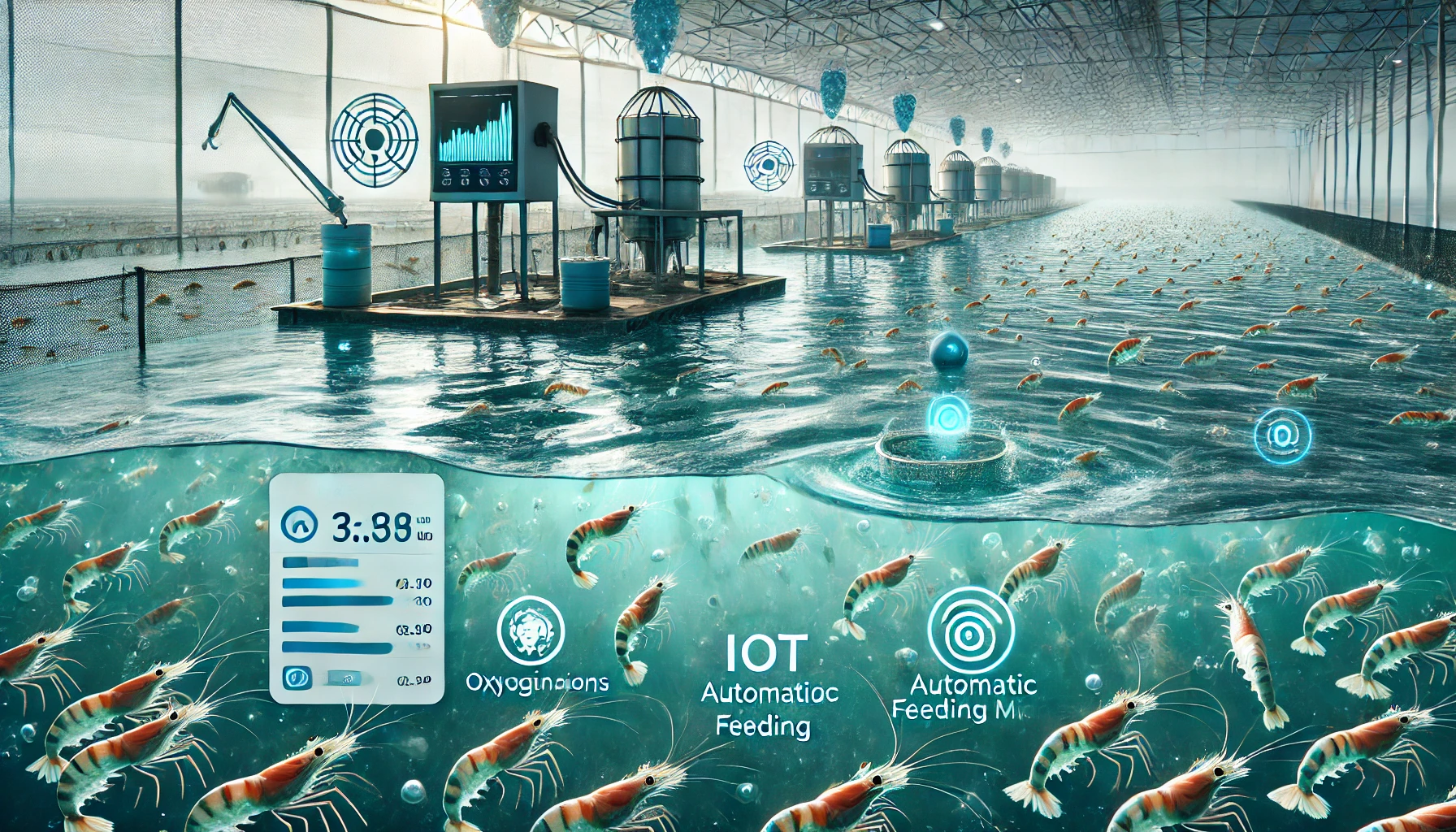

Our Aquaculture IoT system leverages the eWON IoT Gateway, integrated with the IoT Thingsboard platform, to collect and manage real-time data from sensors measuring water pH, temperature, DO (Dissolved Oxygen), salinity, and ORP (Oxidation-Reduction Potential). The system enables remote monitoring of critical water quality parameters to ensure an optimal living environment for aquatic species. Additionally, the solution incorporates automated control devices such as water pumps, oxygen aerators, and automatic feeders, allowing for complete automation of aquaculture management processes. Users can configure device schedules or perform manual control through the mobile or web-based application.

The system is also equipped with remote surveillance cameras, providing real-time video feeds and alert notifications when abnormalities are detected. All sensor data and device operation statuses are stored and visualized on the Thingsboard platform, enabling users to monitor, analyze, and make informed decisions to enhance productivity and product quality. The system has been successfully deployed in five shrimp ponds in Nam Dinh and Can Tho, delivering significant improvements in environmental management and increased harvest yield.

Functional Modules:

- User Management & Authorization: Manage user accounts and assign permissions based on roles such as managers, operators, and technicians, ensuring secure access control and oversight of all system activities.

- Aquaculture Pond Management & Access Assignment: Manage detailed information for each pond (area, aquatic species, equipment setup) and assign access rights to responsible staff for each zone, ensuring transparency and effective supervision.

- Digital Aquaculture Pond Map Management: Visualize ponds on a digital map interface, providing an overview of the layout and positions of sensors and control devices, supporting effective navigation and pond management.

- Sensor Data Monitoring: Collect and display real-time environmental parameters such as pH, water temperature, DO (Dissolved Oxygen), salinity, and ORP. Data is analyzed and stored to monitor environmental health and stability.

- Manual Control Management: Enable users to directly control devices such as water pumps, oxygen aerators, and automatic feeders from a centralized interface, facilitating quick interventions when necessary.

- Automated Control Management: Configure automatic control templates and device operations based on predefined sensor value thresholds. The system automatically adjusts device settings to maintain ideal environmental conditions.

- Surveillance Camera Management: Integrate remote surveillance cameras, allowing for real-time video streaming of pond areas, video storage, and alert notifications when unusual motion is detected.

- Notification Management: Set up automated alerts via SMS or email for incidents such as environmental parameter deviations, device malfunctions, or detected motion anomalies, helping users respond promptly to potential issues.

- Reporting & Analytics: Generate periodic reports on environmental parameters, device performance, and aquaculture productivity. Provide data analytics features to support decision-making for process improvement and operational optimization.